Content developed by ALEFIYA SAIFY

A printing press is a mechanical device for applying pressure to an inked surface resting upon a print medium (such as paper or cloth), thereby transferring the ink. It marked a dramatic improvement on earlier printing methods in which the cloth, paper or other medium was brushed or rubbed repeatedly to achieve the transfer of ink, and accelerated the process.

Different types of printing press are

- Relief printing

- Planographic printing

- Screen printing

- Letterpress printing

- Gravure printing

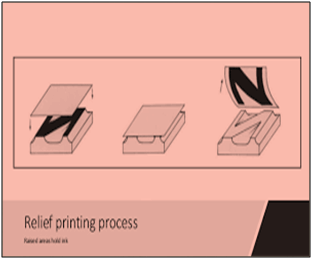

1. Relief printing

- This printing process is developed by John Guttenberg In the 15TH Century.

- The Image area is to print is embossed and the non-image area is empty.

- The basic concept behind this process is that there is a physical disconnection between the image area and the non-image area.

- Firstly, they prepare a Relief printing process. The master is prepared with a mixture of metallic attributes or types of assembled together along with the sample is prepared by photochemical methods, they are known as a block. Both are joined and locked together in a Frame. Ink Rollers on the master apply ink, image is receiving the ink and non-image area does not receive ink.

Example of the Relief printing process is:

Flexography: This type of printing is used in Corrugated boxes, folding cartons, banners, pamphlets, envelops, flexible packing & gift wrapping paper, etc.

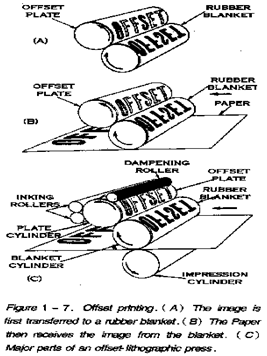

2. Plano Graphic Printing

- It is established on the principle that water and oil do not combine and disguised each other.

- The image area is printed with Greece and oil material and the non-image area is printed by water.

- In this process, the chemical area of both the image is separated. But both rest in the same position.

Example of Plano Graphic Printing is:

Offset Printing: In this type of printing process, the four-color machine and single color machine is used. Newspaper, Magazines, and Books, etc are the example of Offset Printing.

Lithography: This type of printing is used in the microfabrication technique used to make integrated circuits and microchemical systems.

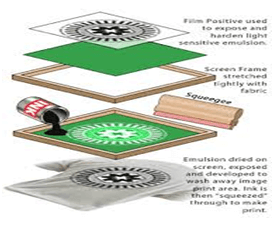

3. Screen printing:-

- This type of printing is used in a wide range.

- Screen printing is more usable then comparison to other Printing processes.

- This is also known as porous printing.

- The process of Screen printing is very simple and unique. It can be done by many things like stitching material, nylon, polyester rubber, plastic, paper & glass, etc.

Examples: Wedding cards and visiting cards etc.

4. Letterpress printing

Letterpress printing is a term for the relief printing of text and image using a press with a ‘type high bed’ printing press and movable type, in which a reversed, raised surface is inked and then pressed into a sheet of paper to obtain a positive right-reading image.

- They are also known as Typography.

- Letterpress printing is also meant for printing borders, rules, illustrations, etc.

- Letterpress printing machines can be classified into three groups.

- Rotary Letterpress Printing, Platen-type letterpress printing and flat-bed Cylinder letterpress.

5. Gravure printing

It is a type of intaglio printing process, which involves engraving the image onto an image carrier. In Direct gravure printing, the ink is applied directly to the cylinder it is transferred to the substrate.

One printing Unit consists of the following components:

- An ink fountain

- A doctor blade assembly

- An impression roller

- A dryer

References

- Mass communication& journalism UGC NETT/SET (JRF & LS)

- Editing: Concepts & Processes (Punjab Technical University)

- Wikipedia